Get In Touch

Get In Touch

Suitable for the production of industrial tires and other high-strength rubber products.

Read MoreThe frame type rubber vulcanizing press is a hydraulic press used for the vulcanization of various types of rubber products.

Read MoreVulcanizing presses for conveyor belts Reliable Vulcanizing Solutions for Conveyor Belt Production Our conveyor belt vulcanizing presses are built with precision engineering and cutting-edge technology. From custom sizes to advanced automation, each press is designed to optimize production efficiency while maintaining strict quality standards. Perfect for large-scale industrial applications and non-standard belt production.

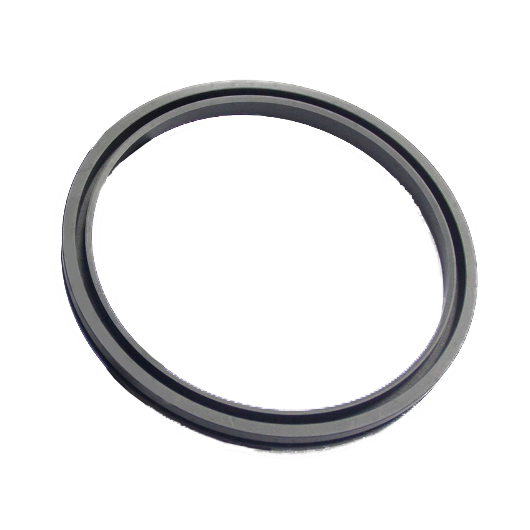

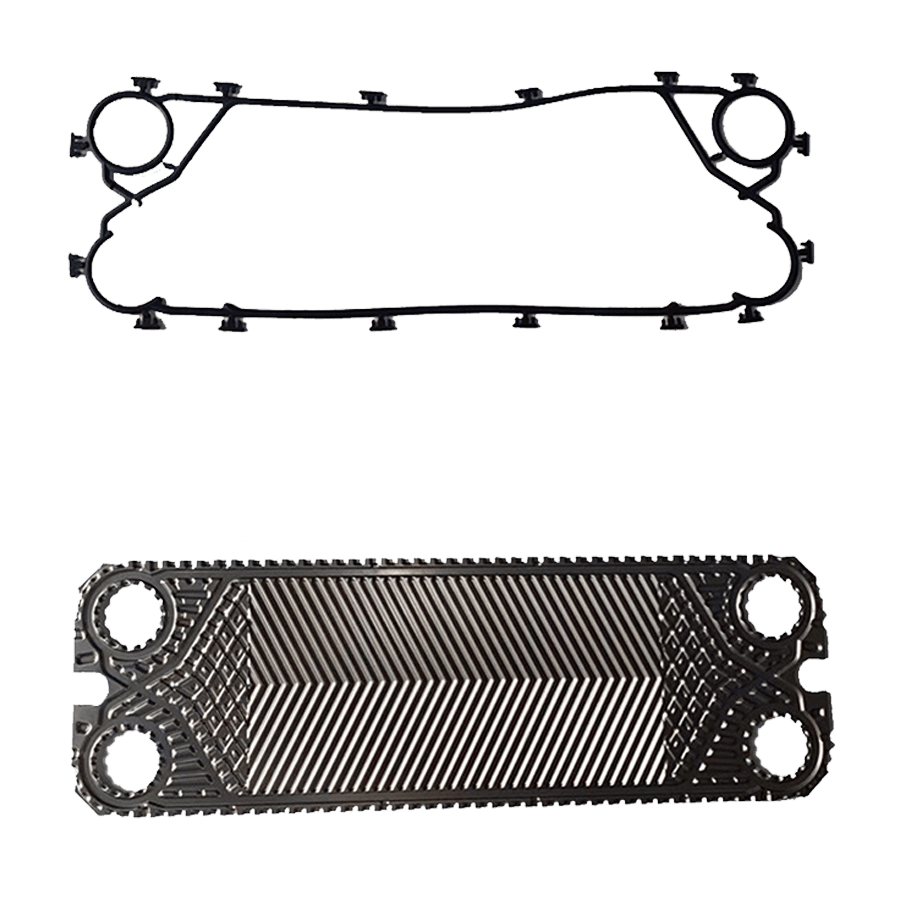

Read MoreOur Vulcanizing Press for Rubber Heat Exchanger Gaskets features high-precision heating and pressure control systems, ensuring even heat and pressure distribution across sealing rings.

Read MoreProduct Overview Model Type: C-Type Vulcanizing Press Certifications: CE, ISO9001, TUV (indicating compliance with international quality and safety standards) Structure: Vertical design with a C-frame structure, providing stability and strength during operation. Customization: Available in various sizes and specifications to meet customer requirements.

Read MoreProduct Overview Model Name: Vacuum Vulcanizing Press Purpose: Designed for vulcanizing rubber and silicone materials in a vacuum environment. Key Benefits: Ensures high-quality finished products by preventing air bubbles and ensuring uniform heat distribution.

Read MoreOur company’s solid tire vulcanizing machine series is mainly used for producing tires for industrial vehicles, such as forklifts, handling vehicles, construction machinery, and other industrial vehicles. These tires feature high load capacity, wear resistance, and puncture resistance.

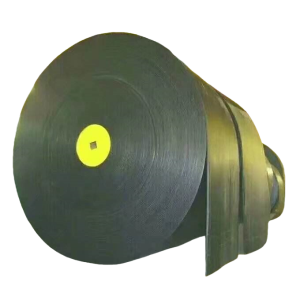

Our company’s conveyor belt production line series is mainly used for producing steel-cord conveyor belts and fabric-core conveyor belts. These products feature high wear resistance and tear strength, making them ideal for handling the transport of heavy materials in industries such as mining, ports, and logistics.

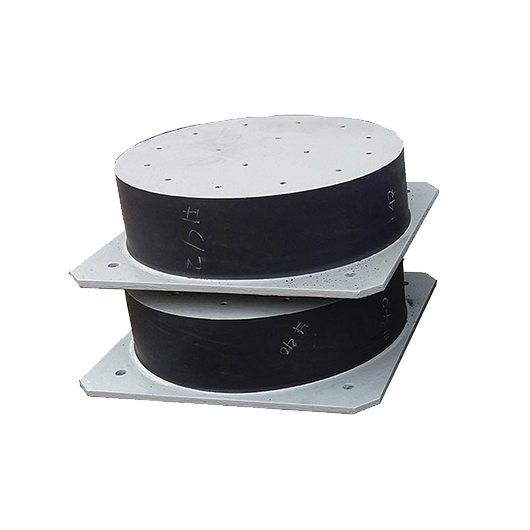

Our company’s series of shock absorber vulcanizing machines is primarily used for producing shock absorber materials, such as bridge bearings, damping pads, pump cores, and other large rubber-metal products. These products are widely applied in bridge engineering, construction engineering, tunnel engineering, marine engineering, and other fields.

The main products include seals, O-rings, oil seals, valve seals, rubber-metal parts, and rubber gaskets. These products are widely used in medical devices, the automotive industry, electronic and electrical industries, industrial machinery, the aerospace industry, consumer goods, and precision instruments. Our equipment is primarily used in the production and processing of these products.

The jaw-type vulcanizing machine series is primarily used for producing rubber tracks, which are mainly applied in large agricultural machinery tracks, excavator tracks, bulldozer tracks, mining equipment tracks, military equipment tracks, and automated warehouse conveyor systems.

These products are widely used in various industries, including chemical, pharmaceutical, food processing, military, HVAC, and power generation. These gaskets are typically used in equipment such as reactors, condensers, heat exchangers, and boilers, aiming to provide excellent sealing and enhance heat exchange efficiency, ensuring the safe and reliable operation of the equipment.

Qingdao Xiangjie Rubber Machinery Manufacturing Co., Ltd. was established in 2004, specializing in production of mechanical equipment for rubber processing industry. Main products include rubber vulcanizing machines, conveyor belt production lines, tire vulcanizing machines, rubber compounding machines and other equipment. Qingdao Xiangjie integrates R&D, manufacturing, sales, and after service. We are a modern large-scale enterprise with leading technological level in China.

Xiangjie's products have been exported to more than 70 countries and regions worldwide, and get reliance from world-renowned rubber product companies. Our company has passed ISO9001 quality system, CE certification, BV certification. It has 25 utility model invention patents and 2 national invention patents. The company also has the honors of "National High-tech Enterprise", "National Major Tech-equipment Intelligent Manufacturing Enterprise", "National Specialized and Sophisticated Technology" and so on.

Industry Experience

Workshop Area

Sales Countries

Staff Count

Dedicated to providing higher standard products and services for global rubber product customers, focusing on customer needs and creating competitive value for clients worldwide.

Over 30 years of industry experience

30+ national-level patented inventions

Meeting various specific production process requirements

Helping customers choose the most suitable product

Providing customized solutions based on customer needs

Produced over 100 conveyor belt production lines

Capable of producing 20,000T large vulcanizing machines

ISO9001, CE, SGS certified

Strict SOP compliance

Equipment undergoes over 72-hour operational testing

Lifetime technical support

Assistance with machine installation and worker training

Experienced overseas engineers for maintenance and repairs

Serving customers in over 70 countries and regions

Highly praised by leading enterprises worldwide, multiple "Best Supplier" awards

Qingdao Xiangjie Rubber Machinery Manufacturing Co., Ltd. is located at No. 333, Juhuashan Road, Tieshan Industrial Park, Huangdao District, Qingdao City, Shandong Province, China.

Yes, we can provide complete solutions according to customer requirements.

Xiangjie has an SOP (Standard Operating Procedure), and all production steps must follow this SOP. Each machine is required to run automatically for over 72 hours and undergoes thorough inspection before shipping.

Yes, we have an experienced pre-sales team that can provide support to customers, including assistance with machine, mold, and auxiliary equipment selection, as well as support for motors, factory layout, and more.

Of course, we have many experienced overseas service engineers who will assist with the installation of machines and provide worker training support.

Actually, the delivery time depends on the type of machine chosen. Typically, for standard machines, the delivery time is within 2-3 months.

The entire machine has a warranty period of 12 months, and the key components of the equipment are covered under warranty as long as the damage is not caused by human factors.

Yes, Xiangjie will provide a set of standard spare parts for the customer based on the specific model of the equipment.