Get In Touch

Get In Touch

Recently, Qingdao Xiangjie Machinery has tailored solid tire vulcanizing machine for customers, downward pressure fabric core conveyor belt production line and other equipment.

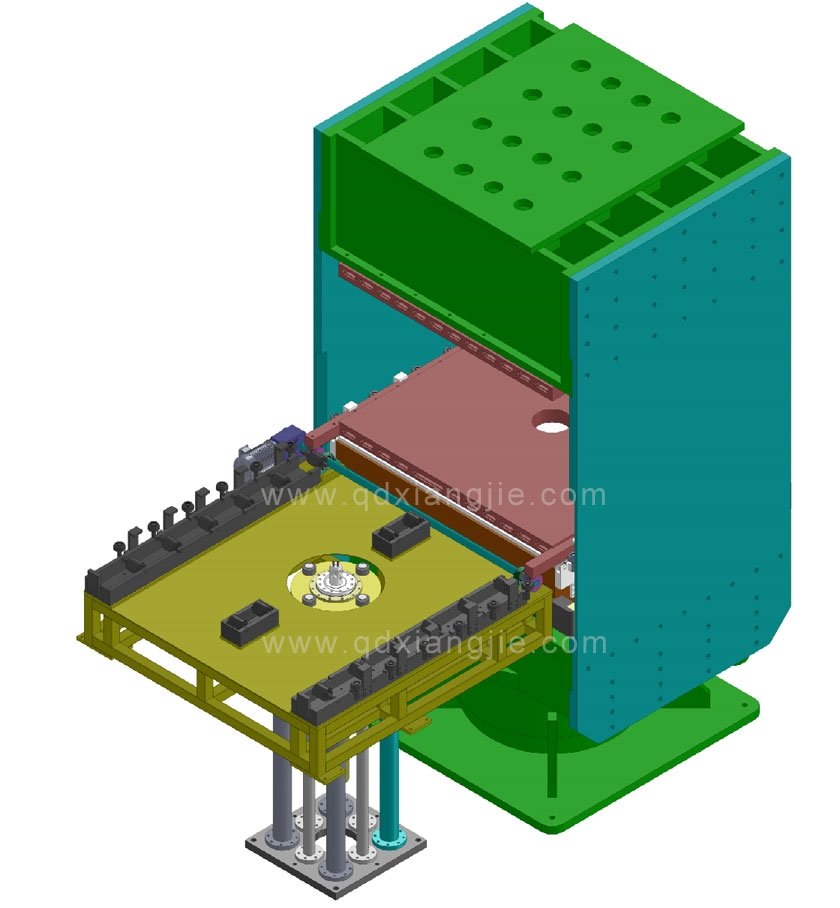

1. XLB-Q2000x2000-1400T solid tire vulcanizing machine

Customer: Continental Germany

Side plate structure

Cylinder: φ1000

Clamping force: 14MN

New hydraulic design, low power consumption and low noise.

The demoulding auxiliary machine is dual-purpose for active mold and ordinary mold.

New hot plate push-pull structure, no push-pull plate, the lower mold is in direct contact with the hot plate, the heat transfer effect is good, and the energy saving

is automatically saved and the pressure and temperature curve of each mold is recorded.

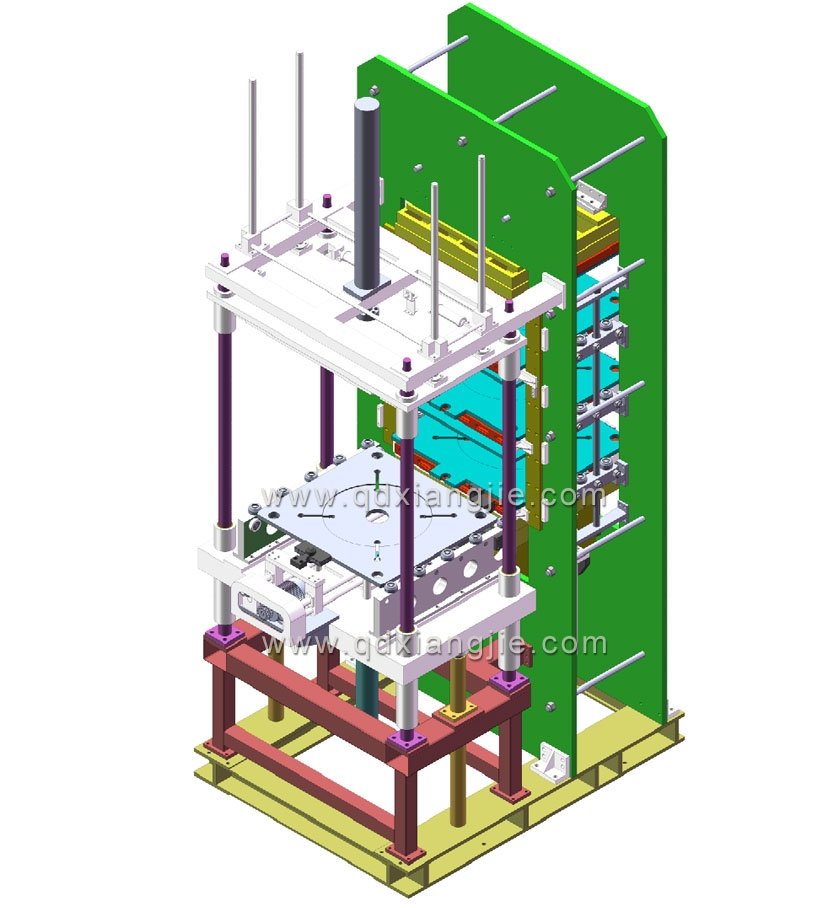

2. XLB-Q1000x1000x4-400T solid tire vulcanizing machine

Frame structure

Cylinder: φ550

Clamping force: 4MN

New hydraulic design, low power consumption and low noise.

The demoulding auxiliary is a multi-layer usable and fully automatic push-pull structure.

There is no need to manually lift the push-pull mold. The mold can be opened and closed in the air to improve efficiency.

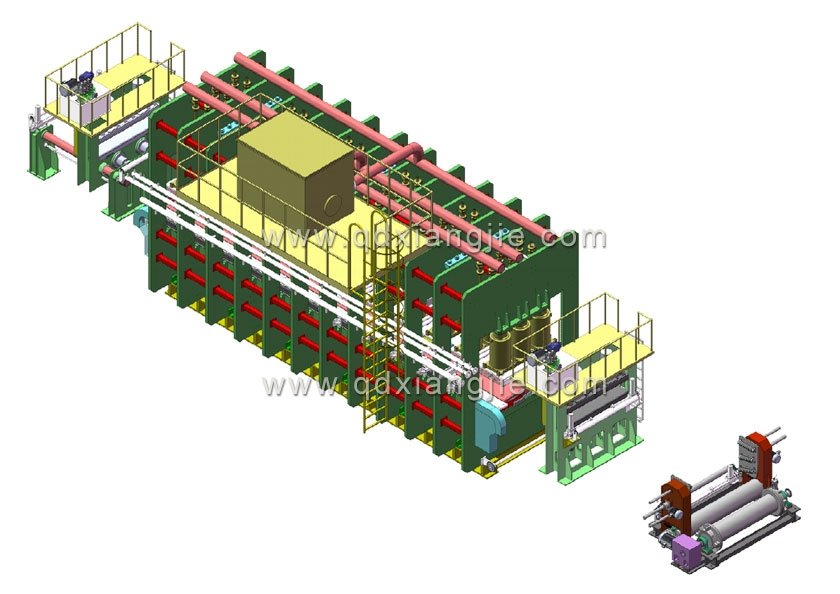

3. 1750X10000, downward pressure fabric core conveyor belt production line

New push-down design.

Cylinder:φ360x6

Clamping force:56MN

New hydraulic design, low power consumption and low noise.

The new design structure of the auxiliary lifting cylinder. It is equipped with mechanical and hydraulic double synchronous lifting mechanism.

Chain type depotting and blessing stretching double depotting system. The whole line is linked, and the data is automatically saved.